Wide flange beams, also known as universal beams, are I-shaped structural steel beams widely used in construction projects like buildings and bridges to support various loads. These beams are available in diverse sizes, and their properties, such as the second area moment of inertia, section modulus, and radius of gyration, can be calculated using a wide flange beam calculator.

Wide flange beams, often referred to as universal beams, are a fundamental structural element in construction. They are distinguished by their I-shaped cross-section, featuring a web connecting two flanges. This configuration, with thicker flanges than the web, provides exceptional strength and stability, making them ideal for supporting substantial loads in various applications. Wide flange beams are a staple in building construction, bridge engineering, and numerous other infrastructure projects.

Their versatility is further enhanced by the availability of a wide range of sizes, each tailored to specific structural requirements. From relatively smaller beams used in light-duty applications to massive beams capable of supporting substantial weight in industrial settings, there’s a wide flange beam size for every need. This broad selection ensures optimal load distribution and structural integrity across diverse construction projects.

The widespread adoption of wide flange beams stems from their cost-effectiveness, ease of installation, and proven track record in structural applications. Their standardized dimensions and properties facilitate design calculations and ensure consistent performance. While their use is prevalent in steel structures, their adaptability and strength make them a valuable component in composite construction as well, further expanding their versatility.

Wide flange beams, often referred to as universal beams, are a fundamental structural element in construction. They are distinguished by their I-shaped cross-section, featuring a web connecting two flanges. This configuration, with thicker flanges than the web, provides exceptional strength and stability, making them ideal for supporting substantial loads in various applications. Wide flange beams are a staple in building construction, bridge engineering, and numerous other infrastructure projects.

Their versatility is further enhanced by the availability of a wide range of sizes, each tailored to specific structural requirements. From relatively smaller beams used in light-duty applications to massive beams capable of supporting substantial weight in industrial settings, there’s a wide flange beam size for every need. This broad selection ensures optimal load distribution and structural integrity across diverse construction projects.

The widespread adoption of wide flange beams stems from their cost-effectiveness, ease of installation, and proven track record in structural applications. Their standardized dimensions and properties facilitate design calculations and ensure consistent performance. While their use is prevalent in steel structures, their adaptability and strength make them a valuable component in composite construction as well, further expanding their versatility.

The diversity of wide flange beam sizes is reflected in their designation, which typically follows the format “W” followed by the nominal depth in inches and the weight in pounds per foot. For instance, a W12x19 beam has a nominal depth of 12 inches and weighs 19 pounds per foot. This simple notation provides a quick reference for identifying the beam’s size and weight, facilitating selection and design calculations.

Beyond the basic dimensions, wide flange beams possess crucial properties that influence their structural behavior. These include⁚

- Section Modulus (Sx)⁚ Represents the beam’s resistance to bending stresses, directly impacting its load-carrying capacity.

- Moment of Inertia (Ix)⁚ Indicates the beam’s resistance to bending deformation, influencing its stiffness and overall stability.

- Radius of Gyration (rx)⁚ Measures the beam’s resistance to buckling, particularly relevant for long spans and slender sections.

These properties are critical for engineers and architects to determine the appropriate beam size for specific structural applications, ensuring adequate strength, stability, and resistance to bending and buckling under anticipated loads.

Wide flange beams, often referred to as universal beams, are a fundamental structural element in construction. They are distinguished by their I-shaped cross-section, featuring a web connecting two flanges. This configuration, with thicker flanges than the web, provides exceptional strength and stability, making them ideal for supporting substantial loads in various applications. Wide flange beams are a staple in building construction, bridge engineering, and numerous other infrastructure projects.

Their versatility is further enhanced by the availability of a wide range of sizes, each tailored to specific structural requirements. From relatively smaller beams used in light-duty applications to massive beams capable of supporting substantial weight in industrial settings, there’s a wide flange beam size for every need. This broad selection ensures optimal load distribution and structural integrity across diverse construction projects.

The widespread adoption of wide flange beams stems from their cost-effectiveness, ease of installation, and proven track record in structural applications. Their standardized dimensions and properties facilitate design calculations and ensure consistent performance. While their use is prevalent in steel structures, their adaptability and strength make them a valuable component in composite construction as well, further expanding their versatility.

The diversity of wide flange beam sizes is reflected in their designation, which typically follows the format “W” followed by the nominal depth in inches and the weight in pounds per foot. For instance, a W12x19 beam has a nominal depth of 12 inches and weighs 19 pounds per foot. This simple notation provides a quick reference for identifying the beam’s size and weight, facilitating selection and design calculations.

Beyond the basic dimensions, wide flange beams possess crucial properties that influence their structural behavior. These include⁚

- Section Modulus (Sx)⁚ Represents the beam’s resistance to bending stresses, directly impacting its load-carrying capacity.

- Moment of Inertia (Ix)⁚ Indicates the beam’s resistance to bending deformation, influencing its stiffness and overall stability.

- Radius of Gyration (rx)⁚ Measures the beam’s resistance to buckling, particularly relevant for long spans and slender sections.

These properties are critical for engineers and architects to determine the appropriate beam size for specific structural applications, ensuring adequate strength, stability, and resistance to bending and buckling under anticipated loads.

While the “W” designation is common, several variations and classifications exist within the wide flange beam family. These distinctions are often based on the manufacturing process, specific properties, or intended applications.

- Standard Wide Flange Beams (W-Beams)⁚ These are the most common type, manufactured to standard specifications and readily available in a wide range of sizes. They are versatile and well-suited for a variety of structural applications.

- Wide Flange Beams with Flange Cuts (WFC)⁚ These beams feature cuts in their flanges, often used to accommodate specific design requirements or to reduce weight while maintaining adequate strength.

- Light Wide Flange Beams (LW-Beams)⁚ These beams are designed for lighter-duty applications and typically have thinner flanges and webs compared to standard W-beams. They are often used in residential construction or situations where weight is a critical factor.

- Intermediate Wide Flange Beams (IW-Beams)⁚ These beams fall between standard W-beams and LW-beams in terms of weight and strength. They offer a balance of strength and weight efficiency, making them suitable for a range of structural applications.

The choice of wide flange beam type depends on factors like the anticipated load, the desired strength, and the overall structural design. Each type possesses unique characteristics that cater to different construction needs, allowing engineers to select the most appropriate solution for their project.

Wide flange beams, often referred to as universal beams, are a fundamental structural element in construction. They are distinguished by their I-shaped cross-section, featuring a web connecting two flanges. This configuration, with thicker flanges than the web, provides exceptional strength and stability, making them ideal for supporting substantial loads in various applications. Wide flange beams are a staple in building construction, bridge engineering, and numerous other infrastructure projects.

Their versatility is further enhanced by the availability of a wide range of sizes, each tailored to specific structural requirements. From relatively smaller beams used in light-duty applications to massive beams capable of supporting substantial weight in industrial settings, there’s a wide flange beam size for every need. This broad selection ensures optimal load distribution and structural integrity across diverse construction projects.

The widespread adoption of wide flange beams stems from their cost-effectiveness, ease of installation, and proven track record in structural applications. Their standardized dimensions and properties facilitate design calculations and ensure consistent performance. While their use is prevalent in steel structures, their adaptability and strength make them a valuable component in composite construction as well, further expanding their versatility.

The diversity of wide flange beam sizes is reflected in their designation, which typically follows the format “W” followed by the nominal depth in inches and the weight in pounds per foot. For instance, a W12x19 beam has a nominal depth of 12 inches and weighs 19 pounds per foot. This simple notation provides a quick reference for identifying the beam’s size and weight, facilitating selection and design calculations.

Beyond the basic dimensions, wide flange beams possess crucial properties that influence their structural behavior. These include⁚

- Section Modulus (Sx)⁚ Represents the beam’s resistance to bending stresses, directly impacting its load-carrying capacity.

- Moment of Inertia (Ix)⁚ Indicates the beam’s resistance to bending deformation, influencing its stiffness and overall stability.

- Radius of Gyration (rx)⁚ Measures the beam’s resistance to buckling, particularly relevant for long spans and slender sections.

These properties are critical for engineers and architects to determine the appropriate beam size for specific structural applications, ensuring adequate strength, stability, and resistance to bending and buckling under anticipated loads.

While the “W” designation is common, several variations and classifications exist within the wide flange beam family. These distinctions are often based on the manufacturing process, specific properties, or intended applications.

- Standard Wide Flange Beams (W-Beams)⁚ These are the most common type, manufactured to standard specifications and readily available in a wide range of sizes. They are versatile and well-suited for a variety of structural applications.

- Wide Flange Beams with Flange Cuts (WFC)⁚ These beams feature cuts in their flanges, often used to accommodate specific design requirements or to reduce weight while maintaining adequate strength.

- Light Wide Flange Beams (LW-Beams)⁚ These beams are designed for lighter-duty applications and typically have thinner flanges and webs compared to standard W-beams. They are often used in residential construction or situations where weight is a critical factor.

- Intermediate Wide Flange Beams (IW-Beams)⁚ These beams fall between standard W-beams and LW-beams in terms of weight and strength. They offer a balance of strength and weight efficiency, making them suitable for a range of structural applications.

The choice of wide flange beam type depends on factors like the anticipated load, the desired strength, and the overall structural design. Each type possesses unique characteristics that cater to different construction needs, allowing engineers to select the most appropriate solution for their project.

The versatility of wide flange beams makes them a cornerstone in diverse construction projects. Their ability to support significant loads, combined with their adaptability and ease of installation, has led to their widespread use in a variety of applications, including⁚

- Building Construction⁚ Wide flange beams are essential structural elements in buildings, supporting floors, roofs, and other structural components. Their strength and stability ensure the building’s structural integrity and safety.

- Bridge Engineering⁚ Wide flange beams are integral to bridge construction, supporting the deck and ensuring the bridge’s stability under heavy traffic and environmental stresses.

- Industrial Facilities⁚ Wide flange beams are used extensively in industrial settings, supporting heavy machinery, storage racks, and other industrial structures.

- Mezzanines and Platforms⁚ Wide flange beams are crucial for creating mezzanines and platforms, providing additional floor space and enhancing the functionality of buildings.

- Other Infrastructure Projects⁚ Wide flange beams find applications in various infrastructure projects, such as parking garages, stadiums, and other large-scale structures.

This wide range of applications highlights the importance of wide flange beams in modern construction, demonstrating their ability to support diverse structural needs and contribute to the safety and functionality of countless structures.

Wide flange beams, often referred to as universal beams, are a fundamental structural element in construction. They are distinguished by their I-shaped cross-section, featuring a web connecting two flanges. This configuration, with thicker flanges than the web, provides exceptional strength and stability, making them ideal for supporting substantial loads in various applications. Wide flange beams are a staple in building construction, bridge engineering, and numerous other infrastructure projects.

Their versatility is further enhanced by the availability of a wide range of sizes, each tailored to specific structural requirements. From relatively smaller beams used in light-duty applications to massive beams capable of supporting substantial weight in industrial settings, there’s a wide flange beam size for every need. This broad selection ensures optimal load distribution and structural integrity across diverse construction projects.

The widespread adoption of wide flange beams stems from their cost-effectiveness, ease of installation, and proven track record in structural applications. Their standardized dimensions and properties facilitate design calculations and ensure consistent performance. While their use is prevalent in steel structures, their adaptability and strength make them a valuable component in composite construction as well, further expanding their versatility.

The diversity of wide flange beam sizes is reflected in their designation, which typically follows the format “W” followed by the nominal depth in inches and the weight in pounds per foot. For instance, a W12x19 beam has a nominal depth of 12 inches and weighs 19 pounds per foot. This simple notation provides a quick reference for identifying the beam’s size and weight, facilitating selection and design calculations.

Beyond the basic dimensions, wide flange beams possess crucial properties that influence their structural behavior. These include⁚

- Section Modulus (Sx)⁚ Represents the beam’s resistance to bending stresses, directly impacting its load-carrying capacity.

- Moment of Inertia (Ix)⁚ Indicates the beam’s resistance to bending deformation, influencing its stiffness and overall stability.

- Radius of Gyration (rx)⁚ Measures the beam’s resistance to buckling, particularly relevant for long spans and slender sections.

These properties are critical for engineers and architects to determine the appropriate beam size for specific structural applications, ensuring adequate strength, stability, and resistance to bending and buckling under anticipated loads.

While the “W” designation is common, several variations and classifications exist within the wide flange beam family; These distinctions are often based on the manufacturing process, specific properties, or intended applications.

- Standard Wide Flange Beams (W-Beams)⁚ These are the most common type, manufactured to standard specifications and readily available in a wide range of sizes. They are versatile and well-suited for a variety of structural applications.

- Wide Flange Beams with Flange Cuts (WFC)⁚ These beams feature cuts in their flanges, often used to accommodate specific design requirements or to reduce weight while maintaining adequate strength.

- Light Wide Flange Beams (LW-Beams)⁚ These beams are designed for lighter-duty applications and typically have thinner flanges and webs compared to standard W-beams. They are often used in residential construction or situations where weight is a critical factor.

- Intermediate Wide Flange Beams (IW-Beams)⁚ These beams fall between standard W-beams and LW-beams in terms of weight and strength. They offer a balance of strength and weight efficiency, making them suitable for a range of structural applications.

The choice of wide flange beam type depends on factors like the anticipated load, the desired strength, and the overall structural design. Each type possesses unique characteristics that cater to different construction needs, allowing engineers to select the most appropriate solution for their project.

The versatility of wide flange beams makes them a cornerstone in diverse construction projects. Their ability to support significant loads, combined with their adaptability and ease of installation, has led to their widespread use in a variety of applications, including⁚

- Building Construction⁚ Wide flange beams are essential structural elements in buildings, supporting floors, roofs, and other structural components. Their strength and stability ensure the building’s structural integrity and safety.

- Bridge Engineering⁚ Wide flange beams are integral to bridge construction, supporting the deck and ensuring the bridge’s stability under heavy traffic and environmental stresses.

- Industrial Facilities⁚ Wide flange beams are used extensively in industrial settings, supporting heavy machinery, storage racks, and other industrial structures.

- Mezzanines and Platforms⁚ Wide flange beams are crucial for creating mezzanines and platforms, providing additional floor space and enhancing the functionality of buildings.

- Other Infrastructure Projects⁚ Wide flange beams find applications in various infrastructure projects, such as parking garages, stadiums, and other large-scale structures.

This wide range of applications highlights the importance of wide flange beams in modern construction, demonstrating their ability to support diverse structural needs and contribute to the safety and functionality of countless structures.

Designing with wide flange beams involves meticulous consideration of several critical factors to ensure structural integrity and safety. These include⁚

- Load Capacity⁚ Accurately determining the anticipated load on the beam, including dead loads (the weight of the beam itself and any permanent fixtures), live loads (occupancy, furniture, equipment), and environmental loads (snow, wind, seismic activity).

- Span Length⁚ The distance between supports, which directly influences the bending moment and shear forces acting on the beam. Longer spans require larger beams with greater section moduli to resist bending stresses.

- Material Properties⁚ Selecting the appropriate steel grade based on strength requirements and anticipated loads. Different steel grades offer varying yield strengths and tensile strengths, influencing the beam’s capacity to withstand stress.

- Connections⁚ Ensuring proper connections between the beam and other structural elements, using appropriate fasteners, welds, or other connection methods to transmit loads effectively and maintain stability.

- Buckling⁚ Considering the potential for buckling, especially in long spans or slender sections. Buckling occurs when a beam under compression fails due to lateral instability. Proper design considerations, such as using stiffeners or reducing the span length, can mitigate buckling risks.

By carefully addressing these design considerations, engineers can ensure that wide flange beams function effectively and safely, contributing to the overall structural integrity of the project.

Wide Flange Beams⁚ A Comprehensive Guide

Introduction to Wide Flange Beams

Wide flange beams, often referred to as universal beams, are a fundamental structural element in construction. They are distinguished by their I-shaped cross-section, featuring a web connecting two flanges. This configuration, with thicker flanges than the web, provides exceptional strength and stability, making them ideal for supporting substantial loads in various applications. Wide flange beams are a staple in building construction, bridge engineering, and numerous other infrastructure projects.

Their versatility is further enhanced by the availability of a wide range of sizes, each tailored to specific structural requirements. From relatively smaller beams used in light-duty applications to massive beams capable of supporting substantial weight in industrial settings, there’s a wide flange beam size for every need. This broad selection ensures optimal load distribution and structural integrity across diverse construction projects.

The widespread adoption of wide flange beams stems from their cost-effectiveness, ease of installation, and proven track record in structural applications. Their standardized dimensions and properties facilitate design calculations and ensure consistent performance. While their use is prevalent in steel structures, their adaptability and strength make them a valuable component in composite construction as well, further expanding their versatility.

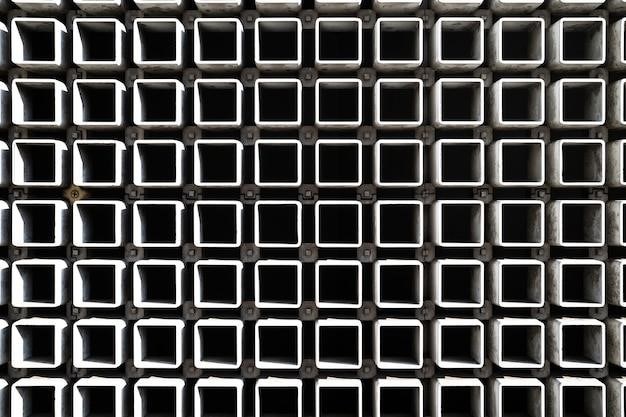

Wide Flange Beam Sizes and Properties

The diversity of wide flange beam sizes is reflected in their designation, which typically follows the format “W” followed by the nominal depth in inches and the weight in pounds per foot. For instance, a W12x19 beam has a nominal depth of 12 inches and weighs 19 pounds per foot. This simple notation provides a quick reference for identifying the beam’s size and weight, facilitating selection and design calculations.

Beyond the basic dimensions, wide flange beams possess crucial properties that influence their structural behavior. These include⁚

- Section Modulus (Sx)⁚ Represents the beam’s resistance to bending stresses, directly impacting its load-carrying capacity.

- Moment of Inertia (Ix)⁚ Indicates the beam’s resistance to bending deformation, influencing its stiffness and overall stability.

- Radius of Gyration (rx)⁚ Measures the beam’s resistance to buckling, particularly relevant for long spans and slender sections.

These properties are critical for engineers and architects to determine the appropriate beam size for specific structural applications, ensuring adequate strength, stability, and resistance to bending and buckling under anticipated loads.

Types of Wide Flange Beams

While the “W” designation is common, several variations and classifications exist within the wide flange beam family. These distinctions are often based on the manufacturing process, specific properties, or intended applications.

- Standard Wide Flange Beams (W-Beams)⁚ These are the most common type, manufactured to standard specifications and readily available in a wide range of sizes. They are versatile and well-suited for a variety of structural applications.

- Wide Flange Beams with Flange Cuts (WFC)⁚ These beams feature cuts in their flanges, often used to accommodate specific design requirements or to reduce weight while maintaining adequate strength.

- Light Wide Flange Beams (LW-Beams)⁚ These beams are designed for lighter-duty applications and typically have thinner flanges and webs compared to standard W-beams. They are often used in residential construction or situations where weight is a critical factor.

- Intermediate Wide Flange Beams (IW-Beams)⁚ These beams fall between standard W-beams and LW-beams in terms of weight and strength. They offer a balance of strength and weight efficiency, making them suitable for a range of structural applications.

The choice of wide flange beam type depends on factors like the anticipated load, the desired strength, and the overall structural design. Each type possesses unique characteristics that cater to different construction needs, allowing engineers to select the most appropriate solution for their project.

Wide Flange Beam Applications

The versatility of wide flange beams makes them a cornerstone in diverse construction projects. Their ability to support significant loads, combined with their adaptability and ease of installation, has led to their widespread use in a variety of applications, including⁚

- Building Construction⁚ Wide flange beams are essential structural elements in buildings, supporting floors, roofs, and other structural components. Their strength and stability ensure the building’s structural integrity and safety.

- Bridge Engineering⁚ Wide flange beams are integral to bridge construction, supporting the deck and ensuring the bridge’s stability under heavy traffic and environmental stresses.

- Industrial Facilities⁚ Wide flange beams are used extensively in industrial settings, supporting heavy machinery, storage racks, and other industrial structures.

- Mezzanines and Platforms⁚ Wide flange beams are crucial for creating mezzanines and platforms, providing additional floor space and enhancing the functionality of buildings.

- Other Infrastructure Projects⁚ Wide flange beams find applications in various infrastructure projects, such as parking garages, stadiums, and other large-scale structures.

This wide range of applications highlights the importance of wide flange beams in modern construction, demonstrating their ability to support diverse structural needs and contribute to the safety and functionality of countless structures.

Wide Flange Beam Design Considerations

Designing with wide flange beams involves meticulous consideration of several critical factors to ensure structural integrity and safety. These include⁚

- Load Capacity⁚ Accurately determining the anticipated load on the beam, including dead loads (the weight of the beam itself and any permanent fixtures), live loads (occupancy, furniture, equipment), and environmental loads (snow, wind, seismic activity).

- Span Length⁚ The distance between supports, which directly influences the bending moment and shear forces acting on the beam. Longer spans require larger beams with greater section moduli to resist bending stresses.

- Material Properties⁚ Selecting the appropriate steel grade based on strength requirements and anticipated loads. Different steel grades offer varying yield strengths and tensile strengths, influencing the beam’s capacity to withstand stress.

- Connections⁚ Ensuring proper connections between the beam and other structural elements, using appropriate fasteners, welds, or other connection methods to transmit loads effectively and maintain stability.

- Buckling⁚ Considering the potential for buckling, especially in long spans or slender sections. Buckling occurs when a beam under compression fails due to lateral instability. Proper design considerations, such as using stiffeners or reducing the span length, can mitigate buckling risks.

By carefully addressing these design considerations, engineers can ensure that wide flange beams function effectively and safely, contributing to the overall structural integrity of the project.

Wide Flange Beam Material

Wide flange beams are primarily made of steel, a material renowned for its strength, durability, and versatility. Steel’s high tensile strength allows it to withstand significant loads, while its ductility enables it to deform under stress without fracturing, enhancing its ability to absorb impact energy and maintain structural integrity. The choice of steel grade plays a critical role in determining the beam’s strength and suitability for specific applications.

Common steel grades used for wide flange beams include⁚

- ASTM A36⁚ A widely used structural steel grade, offering a balance of strength and affordability. It is often used in general construction projects where high strength is not a primary requirement.

- ASTM A572⁚ A higher-strength steel grade, providing increased yield strength and tensile strength compared to ASTM A36. It is suitable for applications where greater load-bearing capacity is necessary.

- ASTM A992⁚ A high-strength, low-alloy steel grade, offering excellent strength-to-weight ratio and resistance to corrosion. It is commonly used in bridge construction and other demanding applications.

- Other Steel Grades⁚ Specialized steel grades, such as those with improved weldability, corrosion resistance, or specific mechanical properties, may be used for specialized applications or to meet unique project requirements.

Selecting the appropriate steel grade is crucial for ensuring the beam’s performance, durability, and safety. The design engineer must carefully consider the anticipated load, the desired strength, and the specific application requirements to choose the optimal steel grade for the wide flange beam.